Identifying electronic components is crucial for circuit board repair and building a spare parts inventory; PDF datasheets are invaluable resources for this process.

The Growing Need for Accurate Component ID

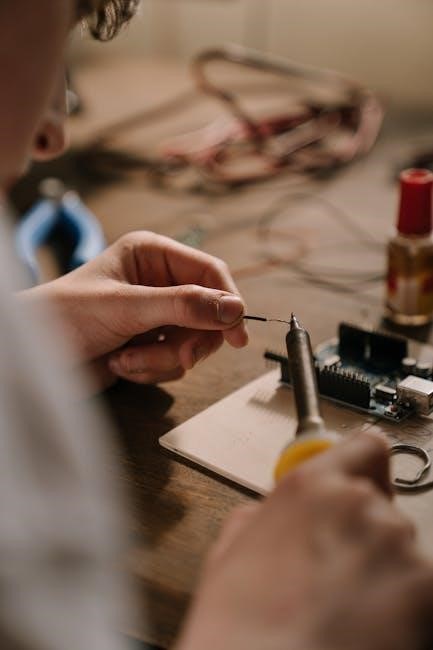

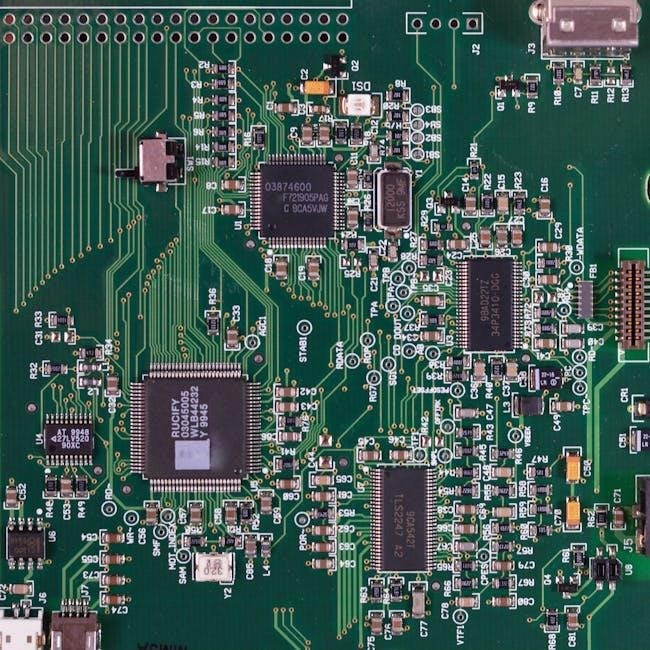

The increasing complexity of modern electronics drives a critical need for precise component identification. Circuit boards now house a vast array of surface-mount and through-hole components, often with minimal or obscured markings. Successful repair, modification, or even reverse-engineering hinges on correctly identifying each part.

Furthermore, the proliferation of counterfeit components poses a significant risk. Accurate identification, aided by comparing datasheets found in PDF format, becomes essential to verify authenticity and prevent failures. Maintaining a functional device requires knowing the exact specifications of each component, readily available within these PDF documents.

Consequently, developing strong component identification skills, coupled with effective PDF datasheet utilization, is no longer just a hobbyist pursuit, but a necessity for professionals and enthusiasts alike.

Scope of this Guide: Focusing on PDF Resources

This guide concentrates specifically on leveraging PDF datasheets for electronic component identification. While visual inspection and component markings are important, we’ll prioritize techniques for extracting information from readily available PDF documentation. We will explore key online databases offering extensive PDF libraries, detailing their strengths and weaknesses.

The focus isn’t on broad electronics theory, but rather on practical methods for decoding component specifications, pinouts, and characteristics within these PDF files. We’ll cover navigating datasheet structures and utilizing search strategies to pinpoint crucial details.

Additionally, we’ll touch upon tools like OCR to handle scanned or image-based PDFs, enhancing the identification process. This guide assumes a basic familiarity with electronic components but aims to empower users to confidently identify parts using PDF resources.

Core Resources: Datasheet Databases

Numerous online databases provide access to vast collections of electronic component datasheets in PDF format, serving as essential tools for identification.

Datasheets.com: A Comprehensive Overview

Datasheets.com stands out as an encyclopedic resource, boasting an extensive collection of datasheets and technical documentation for virtually any electronic component imaginable. This platform is particularly valuable for those needing to identify parts quickly and accurately.

Its strength lies in its sheer volume of information, covering a wide range of manufacturers and component types. The website’s interface allows for both direct datasheet searches, using part numbers when known, and broader category exploration.

Users benefit from readily available PDF downloads, ensuring easy access to detailed specifications and pinout diagrams. The site’s organization and search functionality make navigating its massive database relatively straightforward, solidifying its position as a go-to resource for electronic component identification.

AllDataSheet.com: Features and Functionality

AllDataSheet.com provides a robust platform for sourcing electronic component datasheets, offering a user-friendly experience focused on efficient part identification. The site distinguishes itself through a combination of a large database and practical search tools.

Beyond simple keyword searches, AllDataSheet.com allows users to filter results by manufacturer, category, and specific parameters, refining searches for precise matches. A key feature is its cross-referencing capability, helping to find alternative components with similar specifications.

Like Datasheets.com, it primarily delivers datasheets in PDF format, ensuring compatibility and ease of viewing. The site’s clean layout and responsive design contribute to a positive user experience, making it a valuable asset for engineers and hobbyists alike.

Octopart: Beyond Datasheets ー Part Searching

Octopart differentiates itself from traditional datasheet repositories by functioning as a comprehensive electronic component search engine, extending far beyond simply providing PDF datasheets. It aggregates parts from numerous distributors globally, offering real-time pricing and availability information.

This functionality is invaluable for procurement, allowing users to quickly locate the best deals and check stock levels. Octopart’s parametric search filters are exceptionally detailed, enabling precise component specification searches. It also features a unique ‘Part Number Search’ which can identify components even with incomplete or ambiguous markings.

While datasheets are readily accessible through Octopart, its strength lies in its ability to connect component identification with the practicalities of sourcing and purchasing.

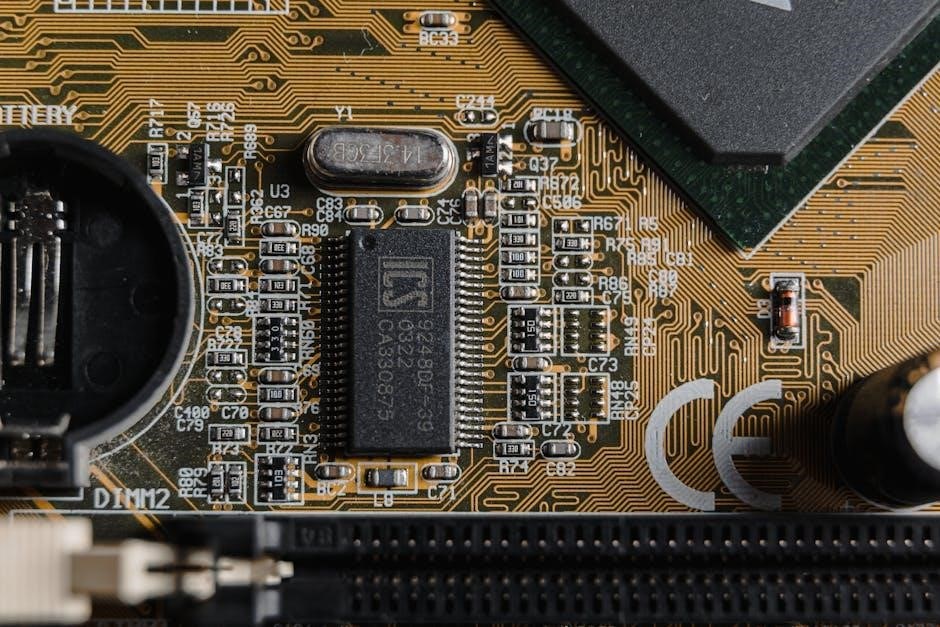

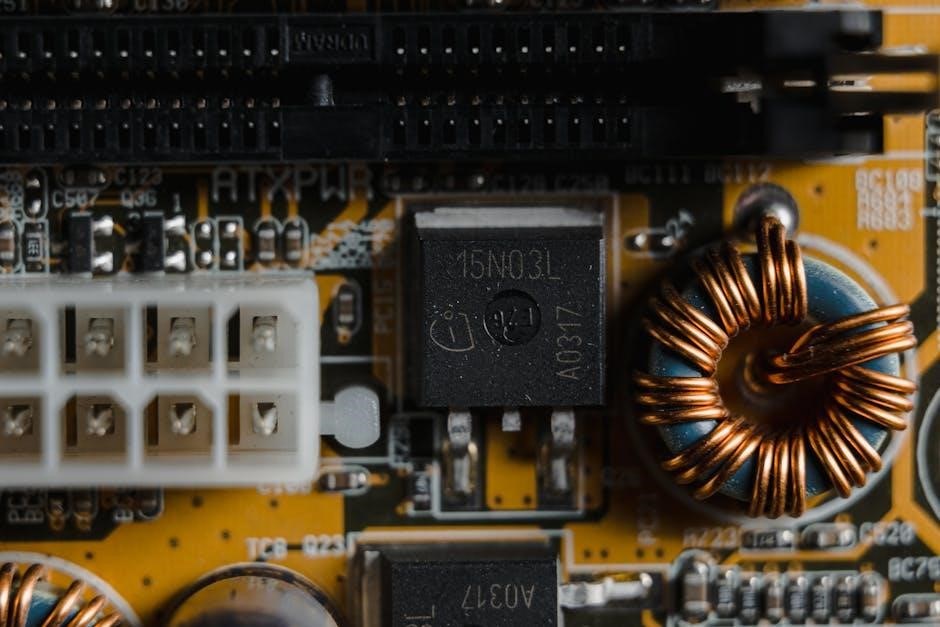

Decoding Component Markings

Component markings, though often cryptic, hold vital clues to identification; understanding date codes, manufacturer IDs, and common schemes unlocks PDF datasheet searches.

Understanding Date Codes and Lot Numbers

Date codes and lot numbers, frequently printed on components, provide crucial manufacturing information, aiding in traceability and identifying potential issues within specific production runs. These markings aren’t directly for identification of the component type, but they’re invaluable when cross-referencing with PDF datasheets.

Manufacturers employ diverse coding systems; some use a numerical week/year format (e.g., 2648 signifies week 26 of 2048), while others utilize alphanumeric schemes. Lot numbers help pinpoint the specific batch a component originated from, useful for investigating failures or recalls.

PDF datasheets often don’t explicitly detail date/lot code meanings, but knowing the manufacturer allows searching their website or contacting support for decoding information. This information, combined with other markings, significantly narrows down potential component matches.

Manufacturer Identification Codes

Electronic components often bear concise manufacturer codes – typically a logo or a short alphanumeric string – crucial for initial identification. These codes are the first step in narrowing down potential PDF datasheet matches, as different manufacturers produce components with similar characteristics.

A comprehensive understanding of common manufacturer markings is essential. For example, a specific symbol might denote Texas Instruments, while another represents ON Semiconductor. Online resources and component databases catalog these codes, facilitating quick lookups.

Once the manufacturer is identified, searching datasheet PDFs specifically from that source becomes far more efficient. Knowing the manufacturer also helps interpret date codes and lot numbers, further refining the identification process. Accurate manufacturer identification is paramount for successful component tracing.

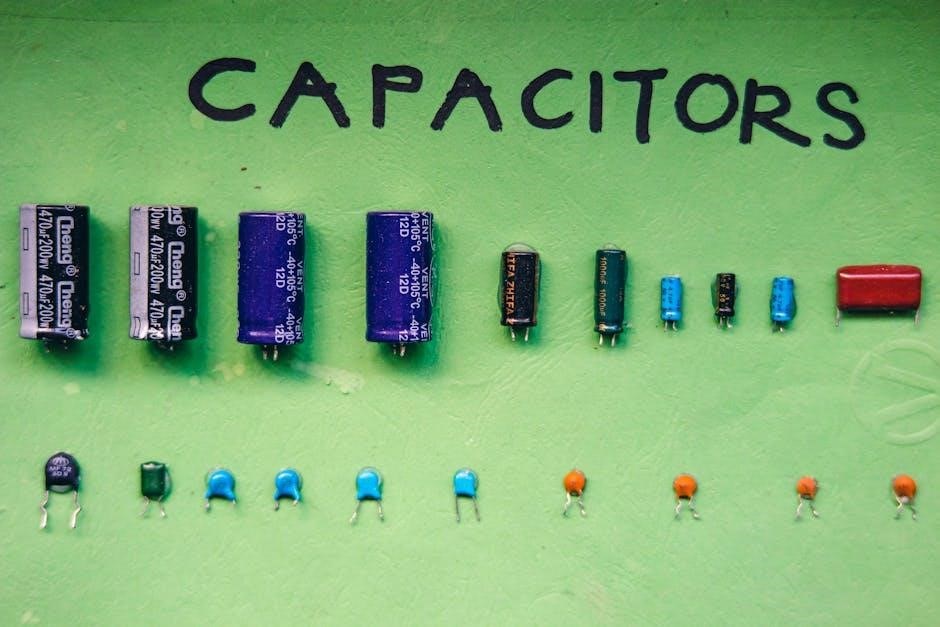

Common Marking Schemes (SMD Resistors, Capacitors, etc.)

Surface Mount Devices (SMDs) utilize compact marking schemes due to size constraints. SMD resistors often employ a three or four-digit code representing resistance value, requiring a decoding chart. Capacitors use similar codes, sometimes including a letter indicating tolerance and temperature coefficient.

Inductors frequently display codes indicating inductance value and tolerance. Integrated circuits (ICs) often have partial part numbers or date codes, necessitating datasheet cross-referencing. Understanding these schemes is vital for PDF datasheet searches.

Decoding these markings requires familiarity with industry standards and manufacturer-specific conventions. Online resources provide extensive tables and calculators for interpreting SMD codes. Accurate interpretation significantly speeds up component identification and allows for targeted PDF datasheet retrieval.

Utilizing PDF Datasheets Effectively

PDF datasheets provide critical details for component identification, including pinouts, electrical characteristics, and package information, enabling accurate circuit analysis and repair.

Navigating Datasheet Structure: Key Sections

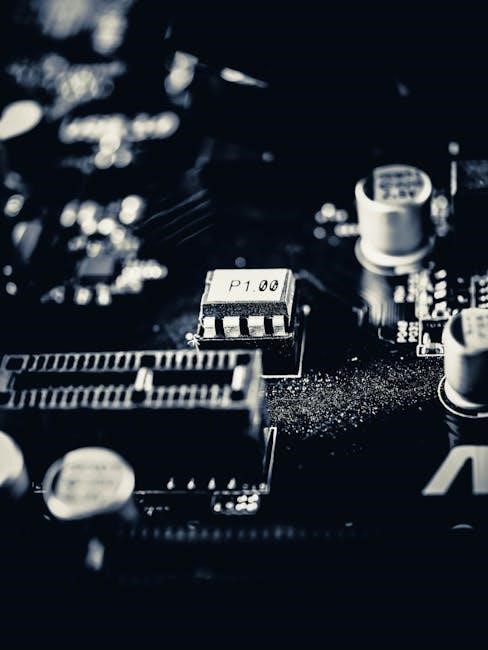

Understanding the typical layout of a PDF datasheet is paramount for efficient component identification. Most datasheets begin with a product overview and key features, providing a concise summary. Following this, you’ll find absolute maximum ratings, defining the safe operating limits of the component.

Electrical characteristics are then detailed, often presented in a table format, specifying parameters like voltage, current, and power dissipation. Pin configurations and package dimensions are crucial for physical integration, usually accompanied by diagrams. Thermal considerations, including thermal resistance, are also frequently included.

Finally, application notes and typical operating circuits offer practical guidance. Recognizing these sections allows you to quickly locate the information needed for accurate component identification and usage.

Pinouts and Package Information in PDFs

Pinout diagrams within PDF datasheets are essential for correctly connecting components. These diagrams clearly illustrate each pin’s function – power, ground, signal input/output – often using symbols and labels. Package information details the physical dimensions of the component, including length, width, and height, vital for board layout.

Datasheets commonly include mechanical drawings with precise measurements, sometimes in both metric and imperial units. Understanding package types (e.g., DIP, SOIC, QFP) is crucial, as they dictate mounting methods. Look for top, side, and end views to fully grasp the component’s physical form.

Carefully comparing the PDF’s pinout and package details with the physical component ensures correct identification and prevents damage during installation or repair.

Electrical Characteristics and Parameters

PDF datasheets meticulously detail a component’s electrical behavior, crucial for verifying its suitability for a specific application. Key parameters include voltage ratings (maximum allowed), current capacity (maximum current flow), and power dissipation (heat generated).

Resistors specify resistance values and tolerance; capacitors detail capacitance, voltage rating, and equivalent series resistance (ESR). Transistors provide parameters like gain (hFE), breakdown voltage, and saturation voltage. Integrated circuits list supply voltage, input impedance, and output characteristics.

Analyzing these parameters ensures the component operates within safe limits and meets the circuit’s performance requirements. Deviations from datasheet specifications can indicate a faulty or counterfeit component.

Advanced Techniques & Tools

Employing strategic PDF search terms, OCR technology, and cross-referencing datasheets with component images significantly enhances identification accuracy and efficiency.

PDF Search Strategies for Specific Components

Effective PDF searching requires a nuanced approach beyond simply typing a part number. Begin with the full component marking, including any prefixes or suffixes, and enclose it in quotation marks for exact matches. If the marking is incomplete or unclear, try searching for partial markings combined with the manufacturer’s identification code.

Utilize Boolean operators like “AND” and “OR” to refine searches. For example, “LM324 AND datasheet” will prioritize results containing both terms. Experiment with different keywords related to the component’s function or application. Consider searching for related terms like “operational amplifier” alongside the partial marking.

Don’t overlook file type restrictions in your search engine. Specifically targeting “filetype:pdf” ensures you only receive PDF documents, streamlining the results. Finally, explore advanced search syntax offered by specific datasheet databases for even greater precision.

Using OCR (Optical Character Recognition) on PDFs

When dealing with scanned PDF datasheets or images of component markings, Optical Character Recognition (OCR) becomes invaluable. OCR software converts images of text into machine-readable text, enabling searching within the PDF even if it wasn’t originally searchable. Several free and paid OCR tools are available, including online converters and software like Adobe Acrobat.

However, OCR isn’t always perfect. Accuracy depends on image quality; clear, high-resolution images yield the best results. Proofread the OCR output carefully, correcting any errors introduced during the conversion process. Focus OCR efforts on sections containing key component markings or datasheets.

Consider using OCR in conjunction with other search strategies for optimal component identification. It’s a powerful tool, but verification with known datasheets remains crucial for accuracy.

Cross-Referencing Datasheets with Component Images

Successfully identifying components often requires combining datasheet information with visual inspection. Once you’ve located a potential datasheet, carefully compare the component’s physical appearance – package type, size, and markings – with images within the document. Pay close attention to pin configurations and any unique features.

Online resources and component databases frequently include images alongside datasheets, facilitating this comparison. Search for images of the component’s markings to confirm a match. Be mindful of variations in packaging or slight differences between manufacturers.

This visual confirmation significantly increases identification accuracy, especially when markings are partial or unclear. Cross-referencing is a vital step in verifying that the datasheet corresponds to the actual component in question.

Troubleshooting Identification Challenges

When facing obscured or missing markings, datasheet comparison becomes essential; identifying counterfeit parts requires careful scrutiny of electrical characteristics and documentation.

Dealing with Obscure or Missing Markings

Component markings can become faded, damaged, or entirely absent due to various factors like age, harsh environments, or deliberate removal. This presents a significant challenge in identification. When direct markings are insufficient, a systematic approach utilizing PDF datasheets is vital. Begin by carefully examining the component’s physical characteristics – package type, size, and number of pins – to narrow down potential candidates.

Next, analyze the surrounding circuitry. Understanding the component’s function within the circuit can provide clues about its type. Utilize datasheet databases, focusing on components commonly used in similar applications. Cross-referencing physical attributes with datasheet specifications is key. If a partial marking is visible, even a single digit or letter, it can serve as a crucial starting point for targeted searches within PDF resources.

Remember to consider manufacturer identification codes, even if incomplete, as these can significantly refine the search process.

Identifying Counterfeit Components via Datasheet Comparison

Counterfeit electronic components pose a serious risk, potentially leading to equipment failure and safety hazards. PDF datasheets are powerful tools for detecting these fakes. A meticulous comparison between the datasheet of a suspected component and the official datasheet from the manufacturer is essential. Pay close attention to electrical parameters, pin configurations, and package dimensions.

Discrepancies in these areas are red flags. Counterfeit components often exhibit deviations from specified tolerances or have incorrect markings. Examine the datasheet’s quality; legitimate datasheets are typically well-documented and professionally presented. Look for inconsistencies in formatting, language, or technical details.

Furthermore, verify the manufacturer’s logo and contact information on the datasheet. If possible, compare the component’s performance against the datasheet’s specifications using testing equipment. A significant mismatch strongly suggests a counterfeit part.